|

|

|

|

Wax Paper Bagging DLG Tail Surfaces

Here's my method for applying fiberglass to balsa tail surfaces:

Place the fiberglass on a sheet of waxpaper and mix some 30 minute epoxy on another piece of wax paper.

Fold a paper towel in half and press it down over the glass to blot some of the epoxy. Peel off the towel and fold it inside out and then press the towel down again to blot the epoxy again.

Lift the wax paper sheet with the wetted fiberglass and place it over the balsa tail surface. Press and smooth the glass onto the tail surface.

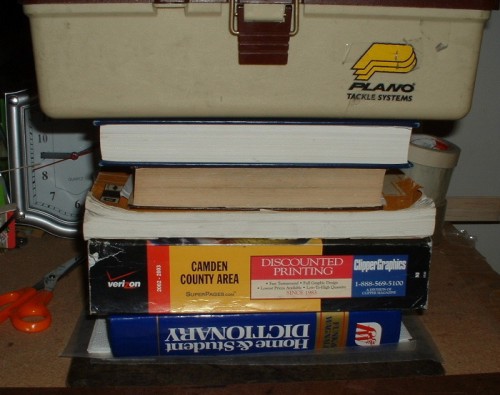

Place eight layers of paper towels on top.

Leave this sit for three or four hours and then remove the weights and turn the wax paper sandwitch over. Carefully remove the top piece of wax paper and fiberglass the other side of the tail surface in the same way. Leave the weights on this for at least three hours.

Trim the extra fiberglass from the tail surface with a razor blade. Glass should conform to rounded edges (that's why you need the paper towels and lots of weight).

For foam surfaces :

This is a fin/rudder for a 34.5" span SAL glider. It is not the size of a fin/rudder for a 1.5 meter DLG. Notes: The beauty of this method is that the equal thickness of paper towels above and below the tail piece, distributes the weight equally above and below the tail surface. This means that a tapered trailing edge is not twisted downward by the weight above, as long as there is equal compressibility above and below the tail piece. Of course this only works as long as the paper towels are not fully compressed. In order to improve the edge contour you can add more weight but you might also need to add thicker layers of paper towels. A flat hard surface both below and above these paper towels is necessary to help distribute the weight evenly - that's the reason for the large hardback book being the first weight on top. Another clipboard (without the clip) could be substituted. Please follow the blotting instructions. If you blot just once, you wind up with too much epoxy and weight. If you blot three times, you wind up with not enough epoxy and the fiberglass can be peeled off the tail surface. Blot twice.I'm not sure that it makes a difference which brand 30 minute epoxy you use, but I use Northeast Hobby Products (NHP) available from Tower Hobbies.

In a perfect world, a bagged object would have equal pressure at each point of the object. In the wax bagging method the thickest part of the airfoil has the most pressure on it.

An alternative to wax paper is the clear plastic acetate normally available in office supply stores. I have not tried it but others have reported good results with it and a more glossy finished surface.

Some people have used a type of urethane foam in addition to or in place of the paper towel cushions. As long as the foam is thick enough and firm enough, it should serve the same purpose. Glassing Foam

It's a good idea to use carbon fiber reinforcement when glassing foam tail surfaces.

The vertical CF on the dlg fin in the photo only needs to go about 65% up from the bottom on each side.

***NEW*** Using Polycrylic Instead of Epoxy

Andy Meysner has been using Polycrylic instead of Epoxy with good success.

|